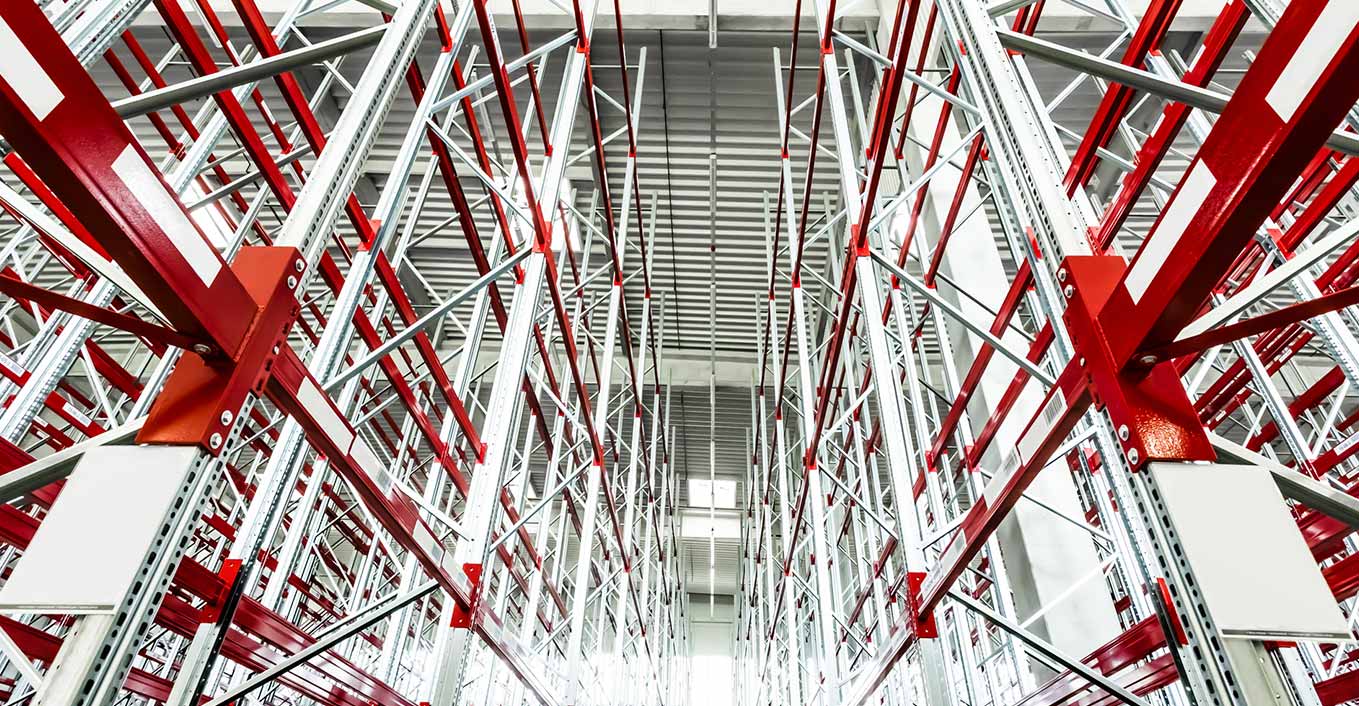

Ease of Assembly with Structural Connections

Manual, semi-automatic and automatic apparatus and machine support are provided, which allow easy application of special shaped cutting processes for projects, assembly applications, finished products and tapes & adhesives requested in line with the needs. It provides process development support services with more than a quarter century of technical knowledge, experience and continuous innovative thinking.

Slicing

Single and double sided industrial tapes, industrial technical sponges and foil papers sliced with high precision between 4 mm and 1650 mm and the requested sizes are prepared.

Full automatic system with precision cutting different widths from each other is carried out quickly and safely.

Besides single and double sided tape, foam tape and closed-cell acrylic; can be made different type of tapes cutting according to project.

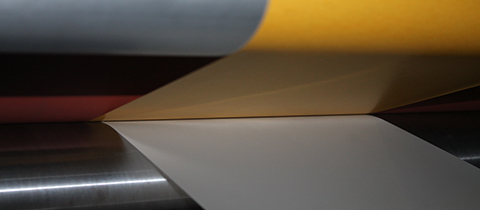

Laminating

The structure of the project, which will be used in applications requiring industrial products and surfaces which is suitable according to the single-sided or double-sided tape with adhesive coating or combined with or in liquid form are prepared in accordance with the sliding method with the demands of. Width up to 1600 mm, according to the structure of the project industrial product that will be used hot or cold lamination process can be provided.

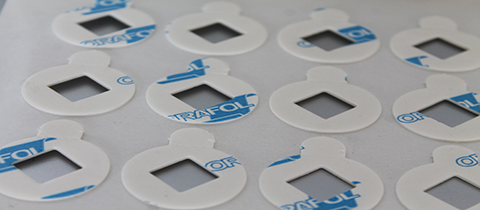

Kiss Cut / Die Cut

Special ways for special projects requested by the customer needed to use in single and double-sided tape, silicone paper with the lamination process is performed after kiss cut or die cut is provided for easy implementation. With kiss cut and die cut process, the product can be transported easily and applied in a practical way.

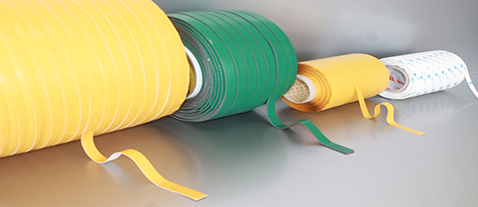

Spool Winding

For mass production, workout is being achieved without long-term change.Single-and double-sided tapes, which may vary between 5 mm and 25 mm are prepared according to the customers’ demand. Industrial tapes, subtracting standard roll lengths on high stakes rollers are transformed into. The tapes length can be prepared as 5,000 meter with demand. Reducing the amount of production lines pause, faster production output can be obtained.

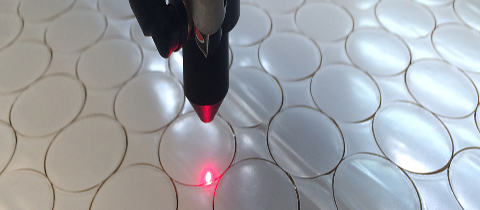

Laser Cutting

The cutting operation is carried out between adhesive tape having a thickness of 0,04 mm and 25 mm, foam and sponges, plastics and other industrial products as well as precise, detailed custom shapes with the laser system.

Applicator Design

All the machine, equipment and field applications for the fast and practical application of the adhesive tapes, the easiness of use is provided by designing the applicator for the bonding solution easily to the surfaces of the adhesive tapes to be used. Continue to make support on tape, adhesive and liquid coating applications for being practical and high quality, time saving with technical equipment solutions.

Sheeting

Industrial tapes, measuring requested size after lamination will be given a flat form. Besides electricity, electronics, printing, advertising and other sectors, the private projects that require shaping are prepared.

Finger Lift

It is possible to make a clean application without touching the adhesive surface during applications and it is ensured that the protective film can be easily separated from the adhesive tape surface after bonding process. In medical, automotive, white appliance, aerospace and printing sectors are provided service with different thicknesses and widths.

CUSTOMER HAPPINESS

PRODUCTION SPEED

ANNUAL GROWTH

PROJECT SUCCESS

Proslıne

Innovative, Industrial Practical Solutions

Fast and easy application with reliable and easy-to-install products